Zindn's four innovative Graphene Zinc Coating products

ZD20-60

Zinc content: 60%

Graphene material: pure thin graphene

VOC: 326g/L

Volume solid content: 64±2%

Mixing density: 2.3±0.1

Finger dry time: 1.0H

Salt spray resistance: ≥4500H

Recommended anti-corrosion environment: C5/CX

ZD6310-Z1550

Zinc content: 40%

Graphene material: ordinary graphene

VOC: 340g/L

Volume solid content: 61±2%

Mixing density: 2.3±0.1

Salt spray resistance: ≥1550H

Recommended anti-corrosion environment: C4/C5

ZD6310-Z850

Zinc content: 30%

Graphene material: ordinary graphene

VOC: 340g/L

Volume solid content: 61±2%

Mixing density: 2.2±0.1

Salt spray resistance: ≥850H

Recommended anti-corrosion environment: C2/C3

ZD6810-Z30 (Aqueous)

Zinc content: 30%

Graphene material: water-based graphene

VOC: 200g/L

Volume solid content: 60±3%

Mixed density: 2.38±0.1

Salt spray resistance: ≥1550H

Recommended anti-corrosion environment: C4/C5

Advantages of Zindn high-performance Graphene Zinc Coating

Advantage one

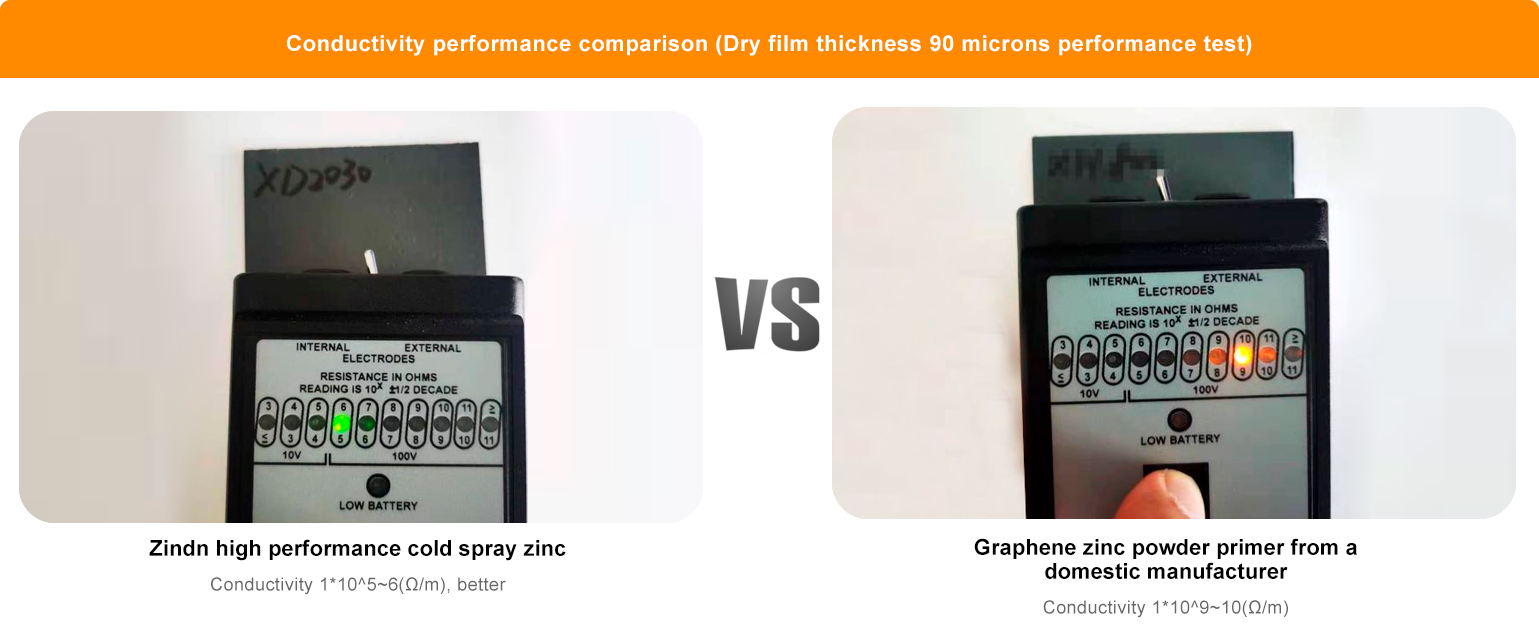

It is resistant to salt spray for more than 4500h, the resistivity reaches 1*10^5~6 (Ω/m), and it can maintain long-term corrosion resistance for more than 25 years in various anti-corrosion environments;

Advantage two

VOC content ≤340g/L, green and environmentally friendly;

Advantage three

The coating rate is high, and the theoretical coating rate of 60 μm film thickness reaches 4.7M^2/KG, which can save more than 15% of the amount of 80% zinc-rich coating;

Advantage four

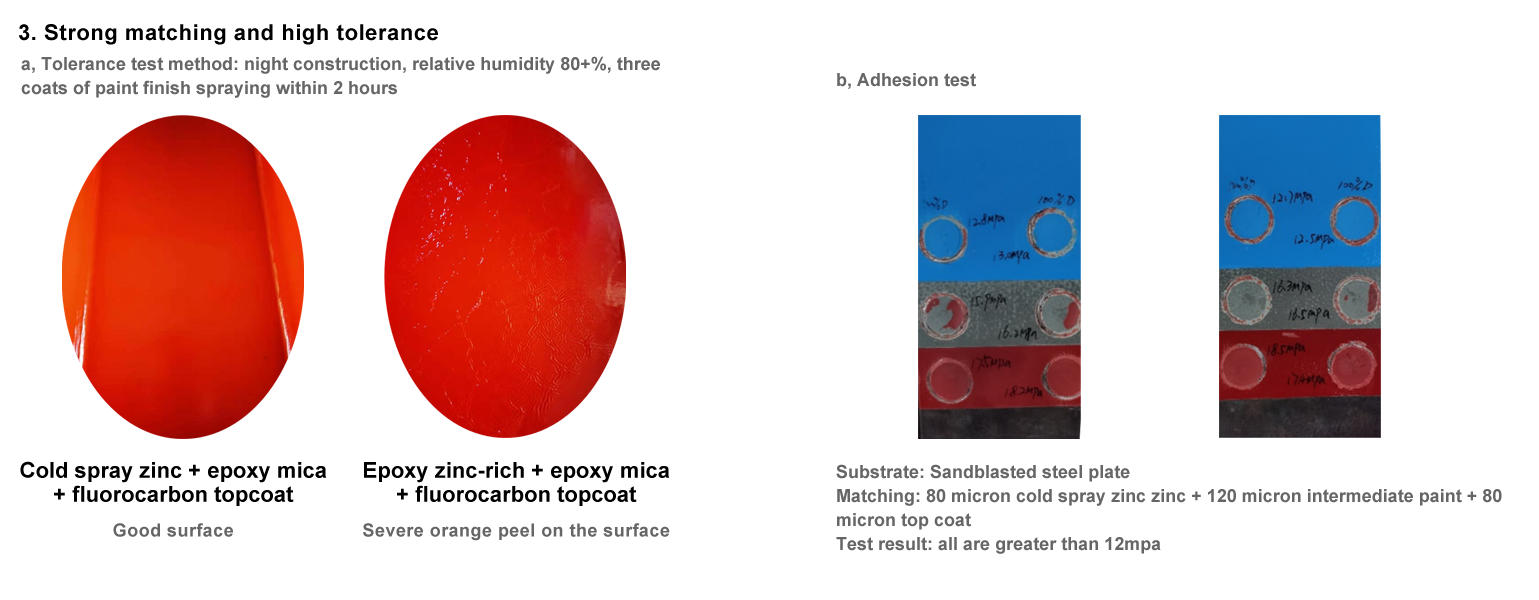

Friendly construction, mature supporting facilities, high and stable adhesion;

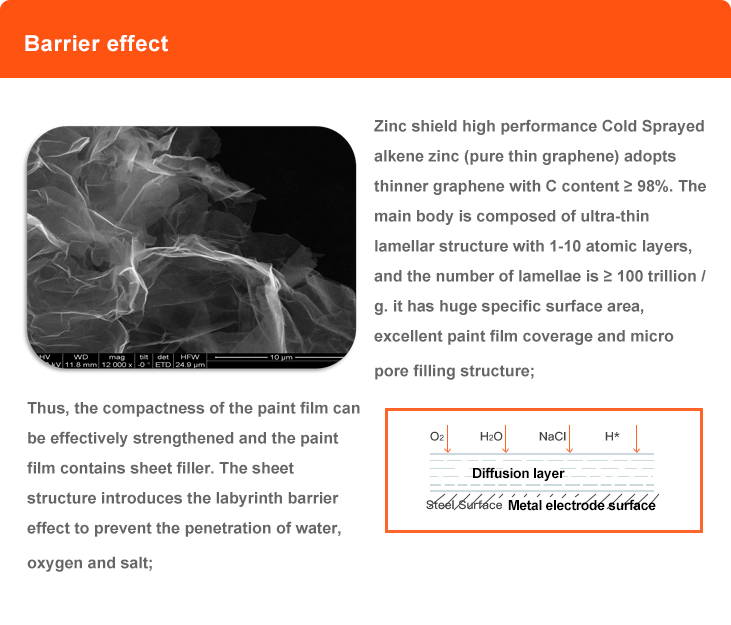

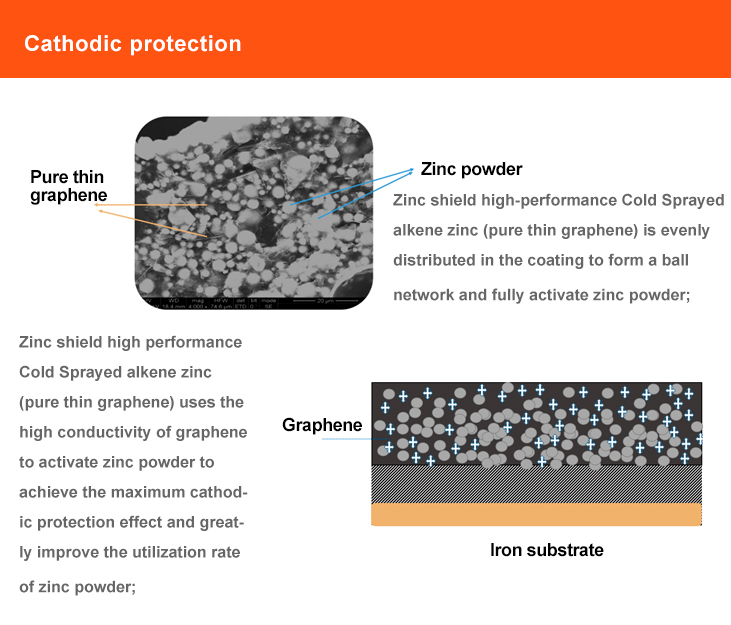

Zindn high-performance Graphene Zinc Coating protection mechanism

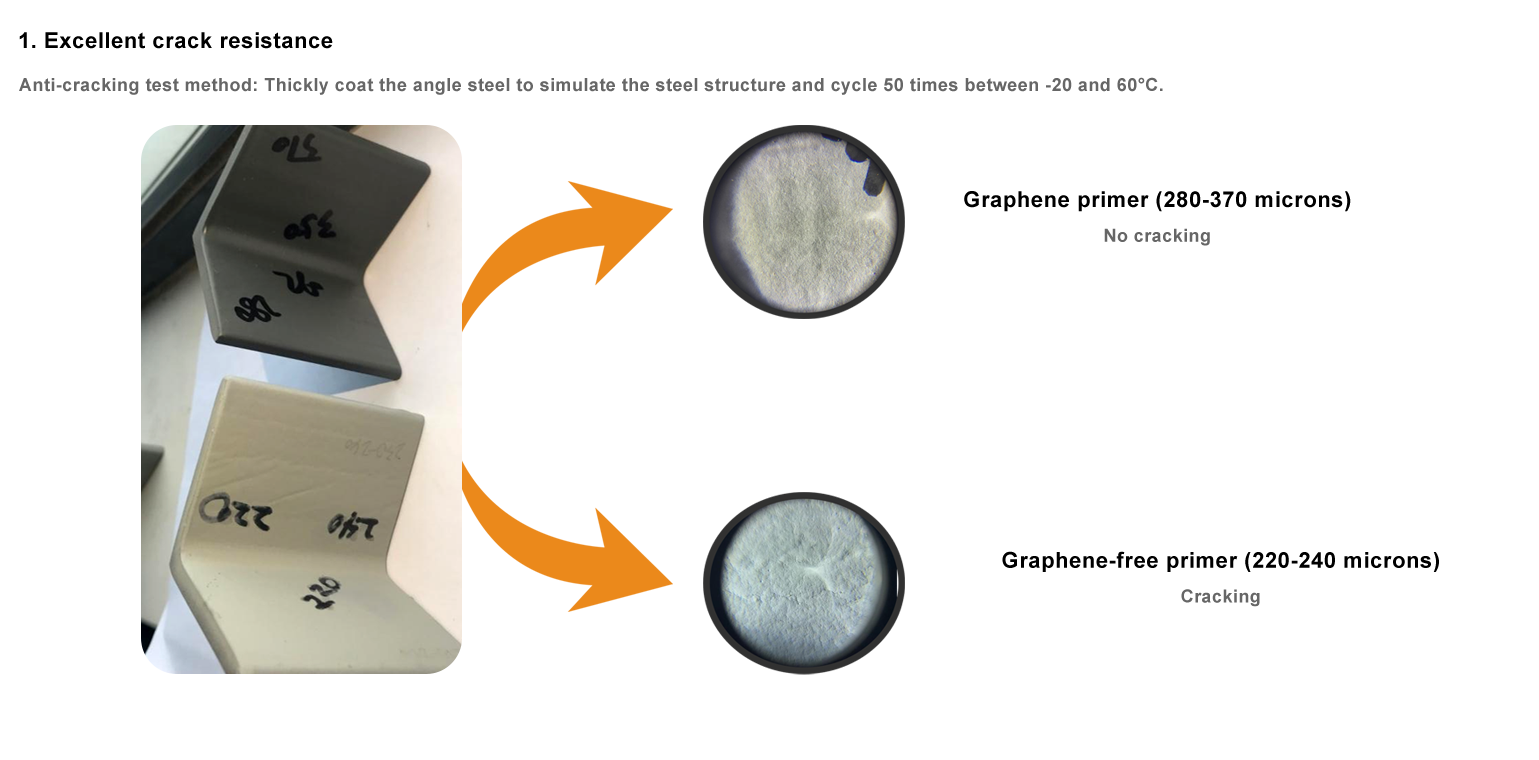

Zindn high-performance Graphene Zinc Coating performance characteristics

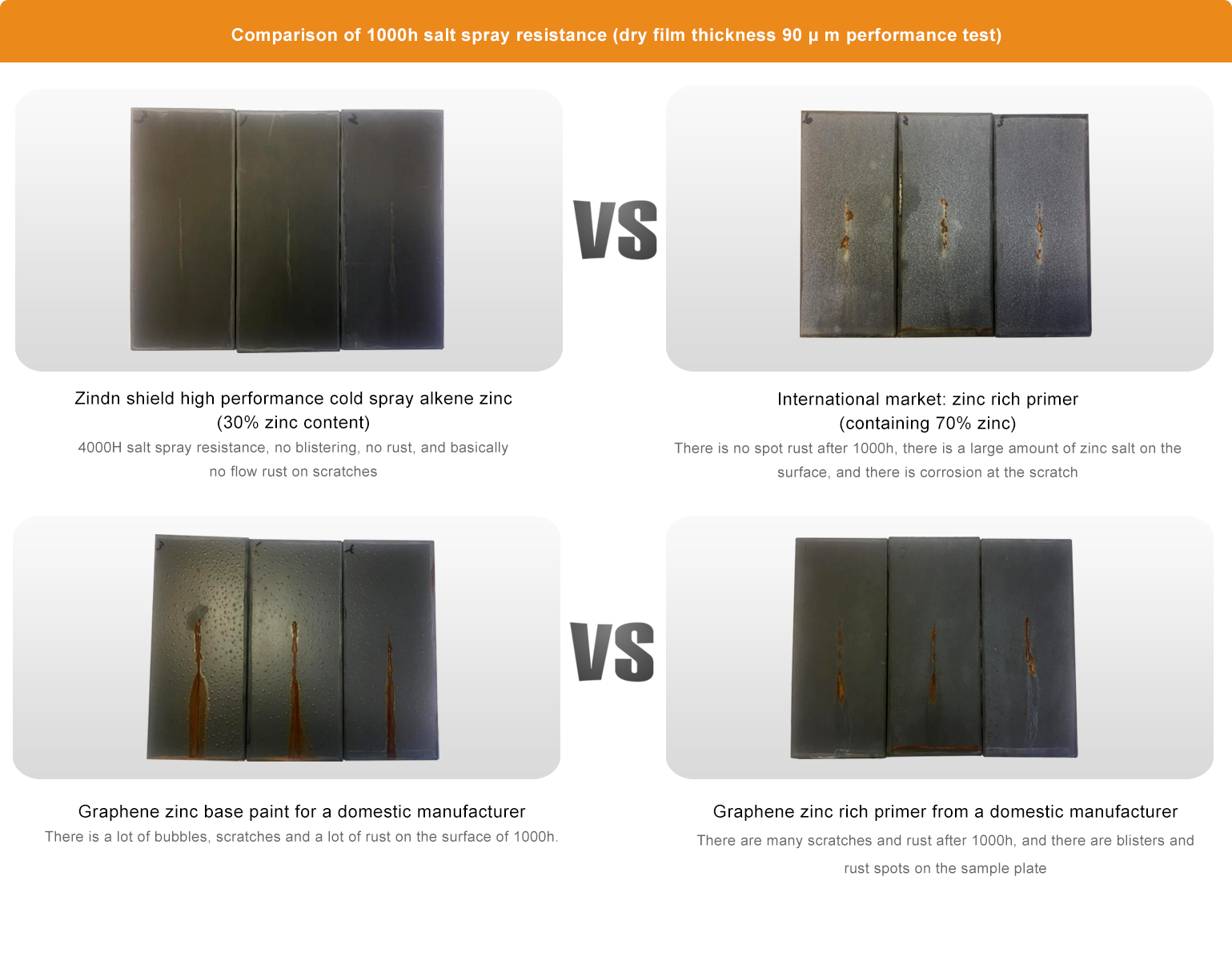

Comparison of Zindn's high-performance Graphene Zinc Coating and its competitors in the market

Zindn High Performance Graphene Zinc Coating Contrast Zinc-Rich Coating

锌盾高性能冷喷烯锌对比富锌涂料

| Compare the item | Zinc rich coating system | Cold spray alkene Zinc system |

| Corrosion resistance test | Salt spray resistance 600 hours (HG-3668) | Salt spray resistance more than 4500 hours |

| Heat and humidity resistance | Generally, single layer exposure to outdoor environment is not allowed | good |

| Cathodic protection performance | Basic barrier protection, plus cathodic protection, part of the damaged area quickly corroded | Good cathodic protection, effectively avoid crevice corrosion, local corrosion |

| Crevice corrosion, local corrosion, acid corrosion | Barrier protection is the main, local corrosion is serious | Good cathodic protection, excellent local corrosion protection, Cold spray alkene zinc composite coating effectively solves acid rain corrosion problem |

| Maintenance cycle | About 5 to 7 years, local improper treatment or bad construction, 1 to 2 years of rust | More than 15 years |

| The construction difficulty | Medium, high requirements for pre-treatment and construction environmental conditions, otherwise easy to crack off phenomenon | Easy, can be in the factory and site convenient construction, the construction environmental conditions for the general requirements |

| Maintenance difficulty | It must be thoroughly polished to the steel body, which is difficult to maintain | It has good recoating performance and low requirement of pretreatment before recoating |

| The cost of | High procurement costs, the whole life cycle of multiple recoating maintenance, direct and indirect losses | Low purchase cost, long-term anti-corrosion, avoid multiple maintenance, corrosion adaptability is good, Convenient construction and maintenance, low life cost |

Zindn high-performance Graphene Zinc Coating application case

Bridge supporting program

Cold spray zinc (80 microns) + epoxy mica intermediate paint (120 microns) + fluorocarbon top coat (80 microns)

Auxiliary equipment supporting plan for offshore wind power equipment

Cold spray zinc 80 microns + epoxy mica intermediate paint 100 microns + polyurethane top coat 80 microns

Environmental protection equipment supporting program

Cold spray zinc 80 microns + epoxy mica intermediate paint 100 microns + polyurethane top coat 80 microns

Special container equipment supporting program

Cold spray zinc 40 microns + epoxy mica intermediate paint 100 microns + polyurethane top coat 40 microns

Wuxi Huadong Zindn Science And Technology Co.,Ltd.

Headquarters contact number:

Free hotline:

86 4006083698

E-mail:

Add:

9th Floor of Wei chuang Building, No.999 Gaolang East Road,Wuxi, Jiangsu, China

Copyright © 2021 Wuxi Huadong Zindn Technology Co., LTD 京ICP证000000号

frankie@zindn.com

frankie@zindn.com +86 18626194558

+86 18626194558 Online message

Online message