Maintenance value-added services

Extend asset life

维修施工前处理

| Steel pretreatment |

|

|

|||||||||||||||||||||

| Rust treatment | |||||||||||||||||||||

Steel materials need to be sandblasted or polished before they can be painted. When sandblasting and polishing, problems such as time-consuming, high noise, high cost, unclean and incomplete substrate treatment, especially maintenance and rust removal, will occur. The pre-treatment is very troublesome, and the rust coating scheme is required at this time. Steel materials need to be sandblasted or polished before they can be painted. When sandblasting and polishing, problems such as time-consuming, high noise, high cost, unclean and incomplete substrate treatment, especially maintenance and rust removal, will occur. The pre-treatment is very troublesome, and the rust coating scheme is required at this time.Zindn is a new generation of water-based rust conversion coating, which dries quickly and has low VOC content. It converts the rust layer on the surface of steel into a protective film that is tightly combined with steel and protects the steel substrate at room temperature. It can completely solve the problem of rust removal during maintenance and construction. |

|||||||||||||||||||||

|

|||||||||||||||||||||

| Low surface treatment | |

|

①Condensation on the surface of the substrate increases; ②Condensation leads to flash rust, causing coating failure; ③The condensed water vapor generated on the surface of the substrate may cause blistering and delamination of the paint film; |

|

|

|||||||||||||||||

维修施工流程

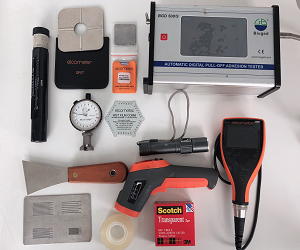

| Zindn maintenance construction qualification | |||

|

|

|||

| Zindn maintenance and construction technical service personnel qualification | |||

|

|

|

|

|

|

|

|

|

| Maintenance engineering business process |

|

| Detailed maintenance engineering business process |

|

|

||||

|

|

||||

|

一、Project admission inspection

|

① Staff formation

|

|

|

|

|

Construction technician

|

Technical staff

|

Coating inspection technician

|

||

|

②Corrosion environment confirmation

|

|

|

|

|

|

temperature humidity

|

Acid-base environment

|

Pollutants

|

||

|

③Layer corrosion detection

|

|

|

||

|

According to the standard ISO 4628 (1-9); GB/T 30789 (1-9)

|

Coating status defects

(Blistering, peeling, aging, cracking, chalking, rusting)

|

|||

|

|

|

|||

|

二、The inspection team proposes |

④Anti-corrosion plan analysis

|

|||

|

|

|

||

|

Corrosion environment analysis

|

Analysis of coating corrosion

|

Budget input

|

||

|

|

|

||

|

Business staff coordination

|

Safety and environmental protection

|

Construction Conditions

|

||

|

|

|

|||

|

三、Program communication and adjustment

|

⑤Program communication and adjustment

|

|||

|

|

|

||

|

Technology R&D Center

|

Production logistics center

|

Inspection team

|

||

|

|

|

|||

|

四、Confirm plan and admission

|

⑥Admission and process control

|

|||

|

|

|

||

|

Construction team

|

Process quality control technician

|

Security and coordination

|

||

Wuxi Huadong Zindn Science And Technology Co.,Ltd.

Headquarters contact number:

Free hotline:

86 4006083698

E-mail:

Add:

9th Floor of Wei chuang Building, No.999 Gaolang East Road,Wuxi, Jiangsu, China

Copyright © 2021 Wuxi Huadong Zindn Technology Co., LTD 京ICP证000000号

frankie@zindn.com

frankie@zindn.com +86 18626194558

+86 18626194558 Online message

Online message